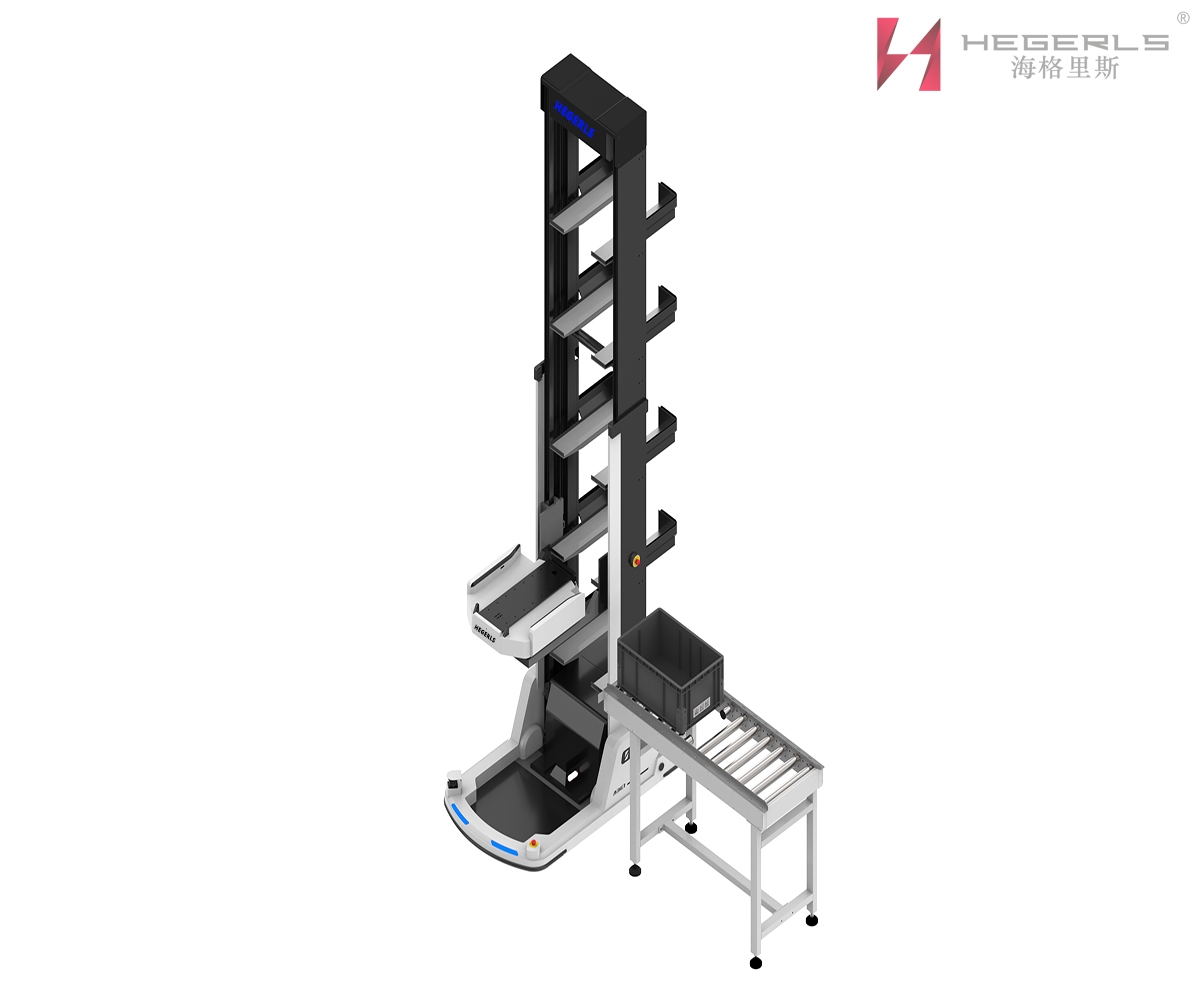

Hegerls A3, a lifting fork picking robot, is not only a "box", but also more than a "box", further expanding the application scenarios of box storage robots. The lifting fork design is adopted to reduce the box spacing to zero and further improve the storage density of the warehouse. Slam laser navigation technology can adapt to more man-machine mixed field operation scenarios. At the same time, it can meet the needs of dust prevention, anti-static, anti pollution and other scenarios. Hegerls A3, a lifting fork picking robot, is equipped with an 8-layer ultra-high back basket, which supports the picking and handling of materials in multiple forms and sizes. It provides a multi-element mixed yard solution for the material turnover scenario and makes warehousing more possible. Hegerls A3, a lifting fork picking robot, independently innovates and develops a lifting fork on the basis of hegerls A3 multi-layer bin robot, which can handle a variety of regular forms of materials. The pickup height covers 330mm~5150mm, flexibly covers the three-dimensional storage space, and greatly improves the storage utilization.

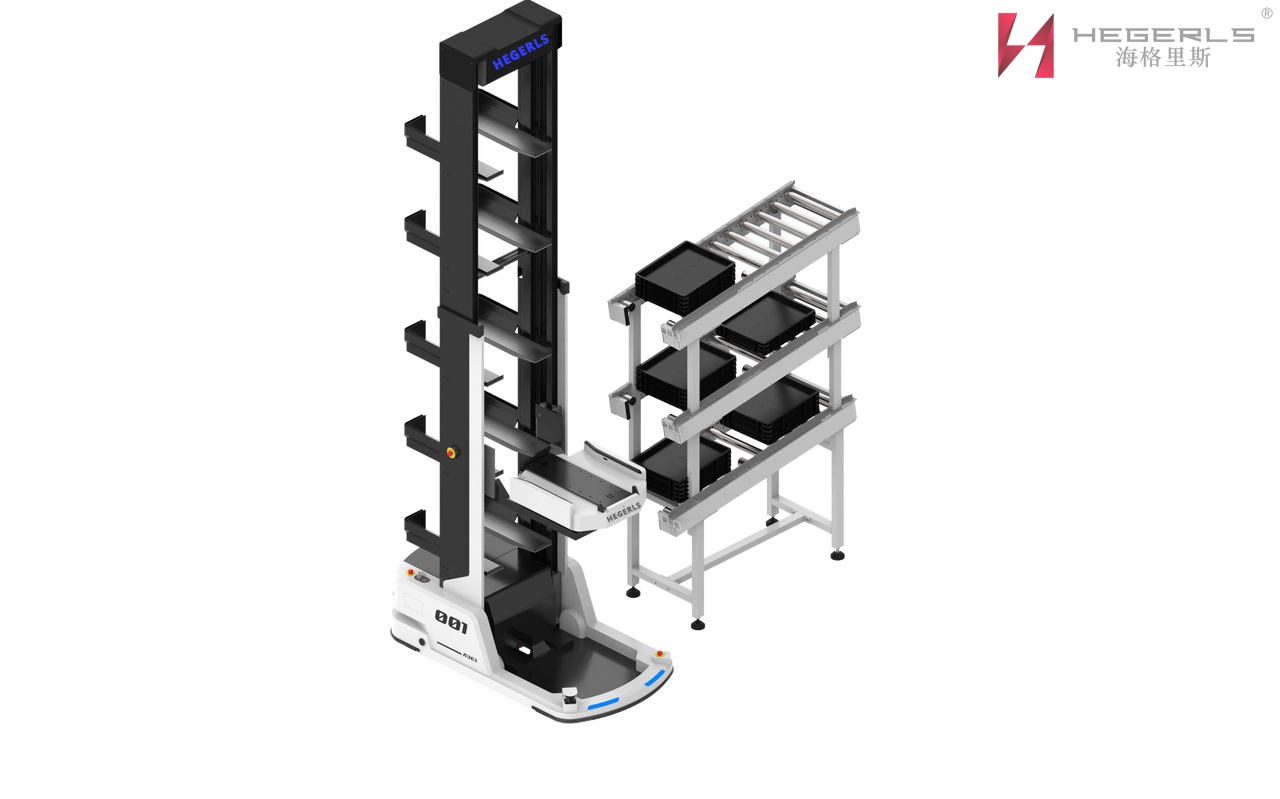

As a new intelligent logistics handling equipment, hegerls A3, a lifting fork picking robot, can realize intelligent walking in the storage space without the help of any track equipment, and has the functions of autonomous navigation, active obstacle avoidance and automatic charging. Compared with the traditional AGV "shelf to person" solution, the picking granularity of the lifting fork picking robot hegerls A3 is smaller. According to the order requirements issued by the system, it truly realizes the transformation from the traditional "people looking for goods" to the efficient and simple "goods to person" intelligent picking mode. Compared with the solutions of stacker and automatic three-dimensional warehouse, the hegerls A3 system of the lifting fork picking robot can be deployed efficiently, with low overall deployment cost and stronger flexibility. Hegerls A3 supports the docking of a variety of logistics equipment, including shelves, conveyor lines, mechanical arms, multi-functional workstations, etc. The flexible and flexible product design brings more operating space for the customized scheme, comprehensively improves the storage operation efficiency, optimizes the storage density, and realizes the automation and intelligent transformation of the storage industry.

Applicable scenarios: applicable to storage scenarios and manufacturing scenarios in retail, medical, 3C, automotive and other industries; In particular, the application of 3C manufacturing, automobile manufacturing, medical manufacturing, lithium battery manufacturing, LED manufacturing and other multi industry manufacturing scenarios.

Functional characteristics of hegerls A3 lifting fork picking robot:

Standard height: flexible 3.9m, customized 0.9m-5.5m;

The design of carrying fork can store the materials in different forms;

Multi container storage, single machine can access up to 8 containers;

The pickup height covers 330mm~5150mm, with an ultra wide three-dimensional storage space;

Hegerls A3, a lifting fork picking robot, has the following advantages:

1) Multiple back baskets, diversity and specifications

Multi back basket - 8-layer back basket, capable of handling 8+1 materials at a time, with a weight of 320kg, leading the industry;

Diversity - a single trip can handle a variety of SKUs, compatible with multi rule materials, and a single machine can handle material boxes, cartons, tires, tray, etc;

Multi specification - support ladder type box gauge mixing yard, more universal shelves, compatible with bracket shelves, cantilever shelves, etc;

2) Fast demand and speed

Demand rapid inventory and accurate delivery of materials;

Hit the target quickly and realize automatic delivery of goods to people;

No load / full load operation speed can reach up to 1.5m/s;

3) Security, stability and picking

Safety, 6 protective measures + dust and static prevention;

Stable operation, no fault in 5000h POC project;

Accurate selection, 99.99% accuracy;

4) Space saving and low cost

Flexible expansion and rapid ROI;

Light transformation with less investment;

The ultra narrow fuselage design saves storage space. The pickup height is generally 4.95M, and the ultra wide three-dimensional storage space.

Post time: Jun-27-2022