Heavy shelf is a common shelf in warehouse storage. Here, heavy shelf is generally used to store pallets or bulk goods, but heavy beam type shelf is another way of saying. Beam type shelf is mainly supported by beams, and most of them choose beam type shelf for storing pallets. Beam type shelf is also called tray type shelf. Pallet shelves play the role of management and storage in the warehouse, with high utilization rate, flexible and convenient inventory, and can basically meet the customer’s storage demand. Shelves are mainly widely used in manufacturing, third-party logistics, distribution centers and other fields, which are not only suitable for the storage of small batches of goods of various types, but also suitable for the storage of large batches of goods.

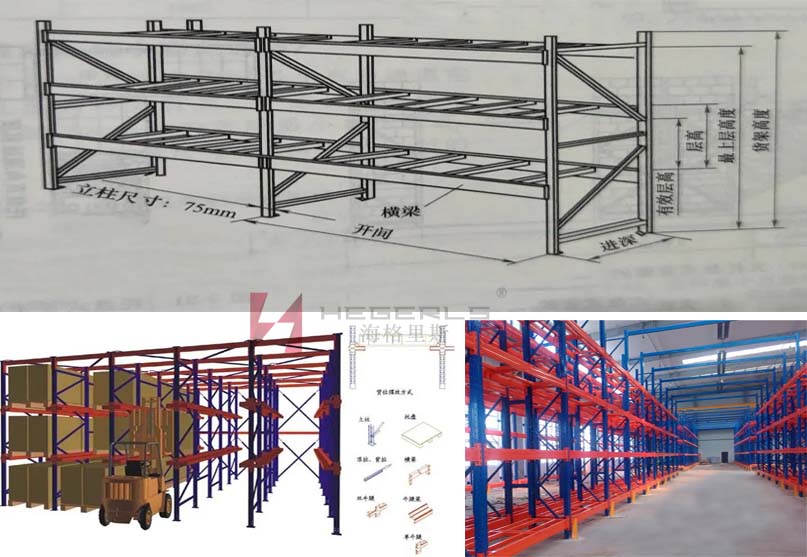

Heavy beam type shelves have the advantages of low cost, rapid installation and disassembly, so they are called the preferred shelf type for enterprises and institutions. The heavy beam type shelf can realize the rapid access of various pallets. The maximum load-carrying capacity of a unit shelf can reach 2000kg, and the shelf height can reach several 10m. During use, it is often necessary to have corresponding loading and unloading machinery and equipment to assist in access. Therefore, during use, the shelf passage needs to be reserved for the passage of loading and unloading equipment.

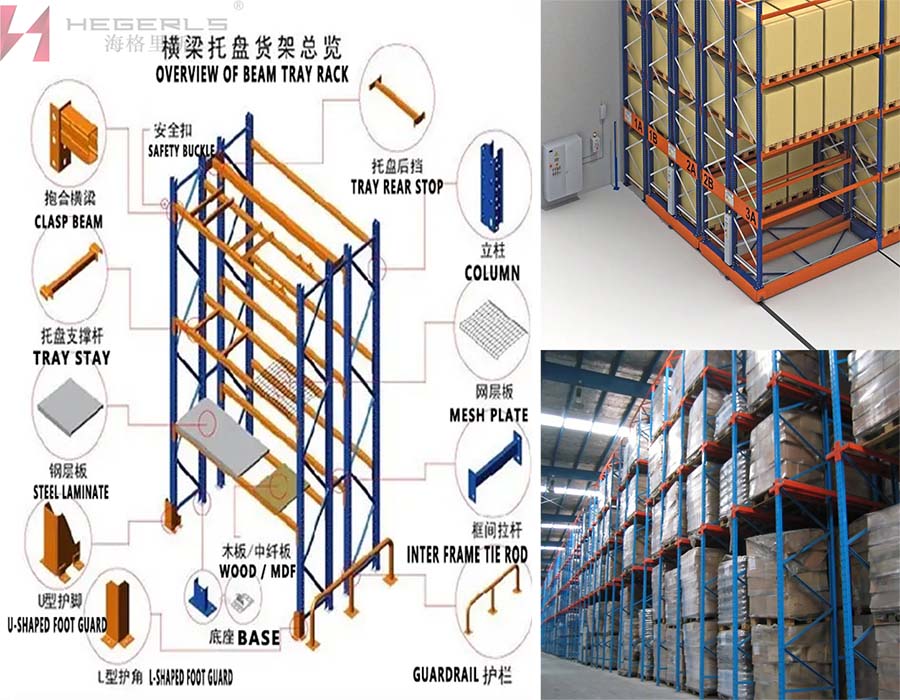

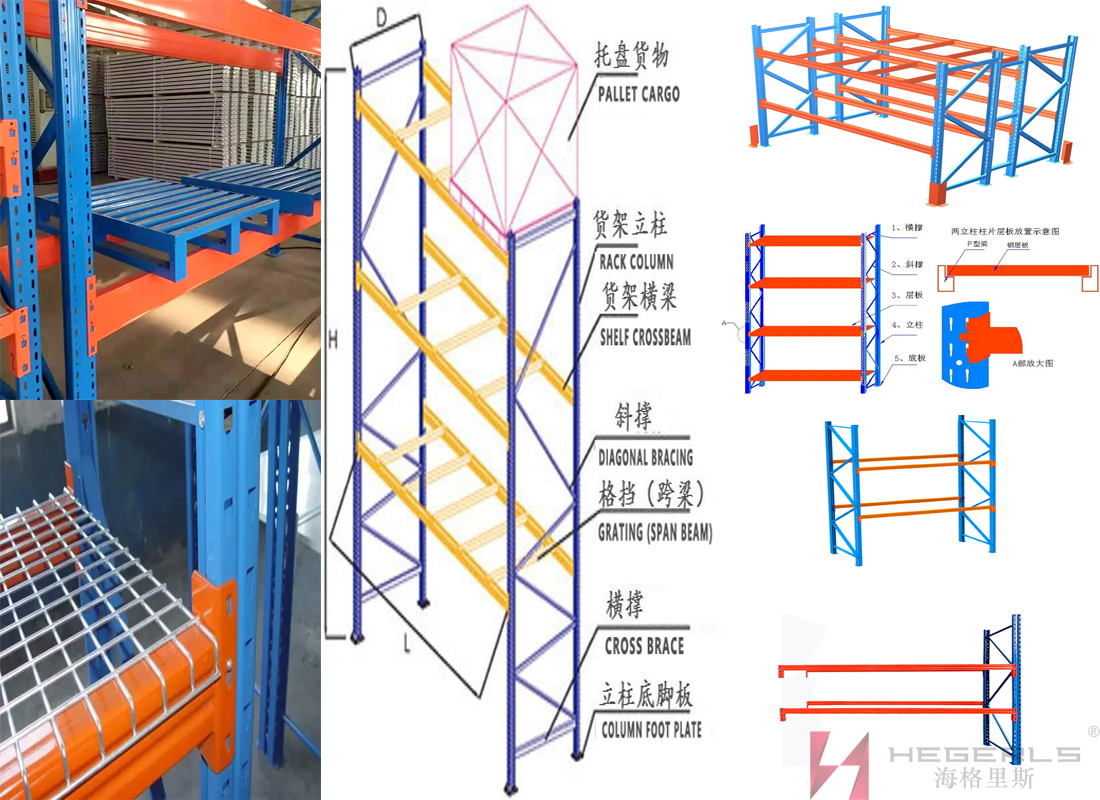

The cross beam rack is generally made of cold-rolled special-shaped steel. The column is made of 80 (90) X60 (70) Ω shaped steel with diamond shaped holes punched on the surface. The cross beam is made of 80×50-100×50-120×50-140×50-160×50 holding welded beams connected with hangers. Generally, pallets are used to replace laminates for convenient forklift transportation. The layer is designed with a load of 1 ton to 5 tons. The surface is electrostatically sprayed with plastic, with stronger waterproof, rust and corrosion resistance, high safety coefficient, plug-in combination, no need for screws and welding, very convenient assembly, making full use of space and providing storage capacity.

The flexible assembly of heavy beam type shelves can achieve different levels of load-bearing according to the size of different beams, the thickness of laminates, and the installation of appropriate stiffeners. When the relative length and material selection requirements meet, the load-bearing will be greater.

Features of heavy crossbeam rack:

1) Used in various industries, it is low-cost, safe and reliable, easy to assemble and disassemble, can be used alone, or can be arranged freely in the form of main and sub frames.

2) Generally speaking, the height of the heavy beam type column is not more than 12M, and the foundation of the attic type shelf is the beam type shelf.

3) The layout is simple, safe and reliable, and can be adjusted and assembled arbitrarily. The goods are not limited by the order of entry and exit. Most of them are pallet based storage and forklift assisted storage.

4) The column piece is composed of columns, cross braces and diagonal braces connected by bolts. The column piece is connected with the C-type holding welding beam to form the shelf frame, which receives the safety pin for fixation, and the layout is simple and reliable. Each layer can freely mediate.

5) It has the characteristics of large inertia moment, strong layer load ability and strong anti strike performance. The maximum layer load of each layer can reach 5000kg / layer under the relative plan.

6) It can further improve the storage height of the warehouse and the space utilization rate of the warehouse. Suitable for storage of various types of goods.

7) Low cost, convenient placement and operation, easy to find cargo location, practical for any handling and paving AIDS, so it is the most widely used shelf.

8) There are also safety reserves at the corners. In case of forklift collision, the foot guards and collision bars of the upper column are added. In order to ensure the safety of the layered load, the crossbeams can also be installed on the crossbeams, such as crossbeam shelves, laminates and mesh cross beams.

The following is different from other shelf manufacturers’ pallet shelves used in forklift operation warehouses.

[hegris heavy beam shelf quality]

The heavy beam type shelf column clamp is equipped with a special designed safety pin when connecting with the column, which can ensure that the beam will not fall off under the impact of external force. The laminate adopts internationally made strip laminates, which are characterized by strong bearing capacity, wear resistance, simple replacement and low maintenance cost.

[size description]

The size of the heavy beam type shelf can be set to 2500 * 1000 * 2000 * 2 layers, the column specification is 90 * 68 * 2.0, the beam specification is 120 * 50 * 1.5, the cross brace specification is 40 * 25 * 1.5, and the bearing weight is 2000kg. The specific specifications can be customized according to customer needs.

[hegris heavy beam shelf material]

The heavy beam type shelf is the most commonly used shelf form and needs to be used with forklifts. The carriers of goods are pallets, storage cages, boxes, etc. the beam type shelf has good accessibility and can load different accessories such as laminates, mesh sheets, cross beams, etc. to meet different use needs.

Hebei Walker metal products Co., Ltd. (hegerls) is an enterprise with an early start in shelves. It has more than 20 years of rich industry experience. Adhering to the service concept of safety, rationality and economy, it provides customers with perfect program design and high-quality products. The types of popular shelves include: attic shelves, through shelves, heavy-duty beam shelves, medium-sized shelves, mold shelves, cantilever shelves, fluent shelves Mobile shelves, shuttle shelves and other storage equipment include: pallets, storage cages, isolation nets, hydraulic lifting platform trucks, logistics trolleys, climbing trucks, steel pallets, material cages, hydraulic forklifts and other non-standard customizable products, which can solve the problem of equivalent rate of goods storage, handling and turnover in one stop.

Post time: Sep-09-2022