Fluent shelf, also known as roller shelf, is an inclined design device with fluent strips on the whole shelf layer. It is composed of column groups, front and rear beams, fluent strips, etc. the goods are transported from the distribution end to the pickup end through the roller track. The goods automatically slide by gravity. It can realize the “first in, first out” operation, one replenishment, multiple picking functions, low cost of use, fast storage speed and high density. Roller type galvanized or aluminum alloy fluent strips are set between the front and rear crossbeams of each shelf layer and placed at a certain slope. The goods are usually cartons or placed in plastic turnover boxes, and their self weight is used to realize the flow of goods and first in first out. The goods are transported by trolleys and accessed manually. The loading capacity of each layer of unit shelves is usually about 1000kg, and the shelf height is within 2.5m. It is applicable to the process conversion on both sides of the assembly line and the picking operation in the distribution center. It can be equipped with electronic tags to realize the information management of goods. Suitable for storage of small goods or products used in sequence.

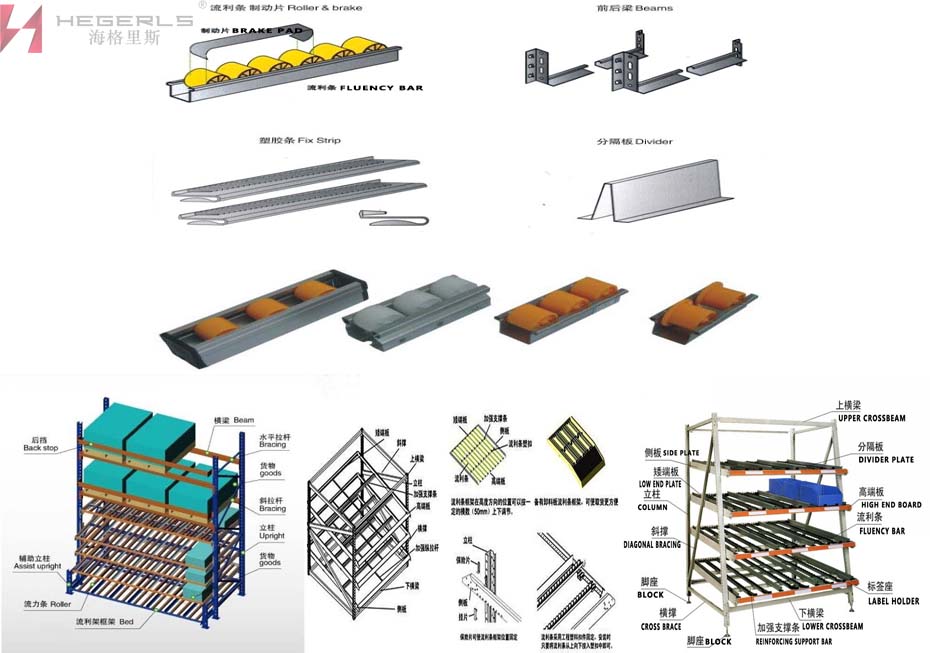

Fluent shelf structure:

1) The rack column is formed by cold-rolled steel plate rolled by a special cold bending forming unit. The front of the column is punched with double rows of holes, and the distance between the holes is arranged in a straight line at a distance of 50mm. The column holes are used for hanging the beam; The two columns are opposite, and the horizontal connecting pipe and the inclined connecting pipe are arranged in the middle to form the column piece of the shelf.

2) The shelf crossbeam is made of p-type pipe, commonly known as ladder beam, and the height of the ladder matches the height of the laminate.

3) The shelves are made of cold-rolled steel plates, which are bent on four sides according to the required size.

4) The crossbeam is connected with the column piece to form a frame, and finally the steel laminate is laid. So far, a complete set of shelves is formed.

5) After the parts of the shelf are processed and formed, they are all processed by grinding, pickling, phosphating, automatic electrostatic powder spraying, drying and other processes to assemble the finished products. The finished surface of the shelf is smooth and beautiful; The shelf layer can be adjusted up and down according to the pitch of 50mm, which is convenient for disassembly and assembly.

Structural features of fluent shelf:

1) Roller type aluminum or sheet metal fluent strips are set between the front and rear beams of each shelf layer;

2) The load capacity of each layer of unit shelves is usually within 1000kg, and the shelf height is within 2.5m;

3) It is suitable for the process conversion on both sides of the assembly line and the picking operation in the distribution center. It can be equipped with electronic tags to realize the information management of goods;

4) The U-shaped groove of fluent bar is made of steel plate, with a bearing capacity of 6kg / shaft, which can work normally at – 40 ° C low temperature;

5) The roller is made of high-quality thermoplastic, with extremely low friction coefficient, excellent impact resistance, strong and non fragile, good acid and alkali resistance, and non hygroscopic.

6) The front and rear gears and side plates are made of bent steel plates. The front and rear gears ensure that the goods can block the goods from leaving the shelf under the action of gravity, and the side plates can allow the goods to slide freely along the flow bar.

The regular colors of fluent shelves are blue, orange and grey. (hegris shelf manufacturer will produce according to the color specified by the customer)

Fluent shelves are divided into heavy-duty fluent shelves and Medium-B shelves. Next, haggis shelf manufacturers will talk about haggis heavy-duty fluent shelves.

Heavy duty fluent shelf is made of roller aluminum alloy, metal plate and fluent bar. The heavy-duty fluent shelf uses the self weight of the shelf to purchase goods from one side of the channel, and the other side is used to pick up goods, so as to realize the first in first out equipment. Heavy duty fluent shelves have high storage efficiency and are suitable for short-term storage and picking of large quantities of goods. Heavy duty fluent shelves can be equipped with electronic tags to facilitate the management of goods. Common sliding containers include turnover boxes, parts boxes and cartons, which are suitable for large quantities of goods and short-term storage and picking.

Heavy duty fluent shelf features:

1) Improve work efficiency: the separation of distribution and picking lanes will not affect each other, and the walking distance of delivery and picking will be reduced by 40% to 70%;

2) Comply with the principle of first in, first out: the materials initially placed on the shelves are first used to help identify quality problems, ensure every link in the production process, and help control the transportation time;

3) Saving construction area: reduce unnecessary roads, saving construction area up to 30%;

4) Ergonomics: materials automatically slide to a reasonable position, making picking easier and easier, reducing fatigue caused by long-term operation.

Application scope of heavy-duty fluent shelves: widely used in manufacturing, commerce, distribution centers, assembly workshops and warehouses, with high delivery frequency.

Working principle of heavy duty fluent shelf:

Heavy duty fluency shelves are equipped with fluency bars, namely slide rails. The goods can slide automatically through the sliding and tilting of the slide rail and its own gravity. The goods are placed on the rollers from the upper end of the tilting slide. The goods slide automatically by gravity, use one side of the channel inventory, and pick up the goods on the other side of the channel to achieve first in, first out, one replenishment and multiple picking.

Using heavy-duty fluent shelves to store materials can save manpower and material protection efficiency, help improve work efficiency, and speed up the production line. The shelf inclines downward toward the transportation direction, and the goods slide downward under the action of gravity to realize the first in first out of goods and facilitate entry and exit. The process conversion on both sides of the assembly line to the sorting operation in the distribution center can be equipped with electronic equipment. Tags, to achieve commodity information management, reduce inventory waste and waste.

Highness is a kind of shelf: attic platform, heavy shelf, cantilever shelf, fluent strip shelf, narrow lane shelf, I-steel platform, mold frame, three-dimensional warehouse shelf, integrated warehouse shelf, light / medium shelf, double depth shelf, push back shelf, electric mobile shelf, auto store shelf, dense shelf / mobile cabinet, shuttle board shelf, drive in shelf, storage cage, workbench A company specializing in the production and processing of storage peripheral equipment and other products, with a complete and scientific quality management system. Haigris’s integrity, strength and product quality have been recognized by the industry. Our company has a professional team with serious work, rich experience and excellent technology, which can complete the design, production and installation of products with quality and quantity within the time required by customers. In order to make the enterprise stand in an invincible position and develop healthily and steadily, the company keeps on developing and setting up forward-looking service contents through its business mode and management system. The company pursues to become a powerful enterprise respected by the society through bit by bit accumulation, hard work and unremitting efforts in the field of commercial equipment industry.

Post time: Sep-08-2022