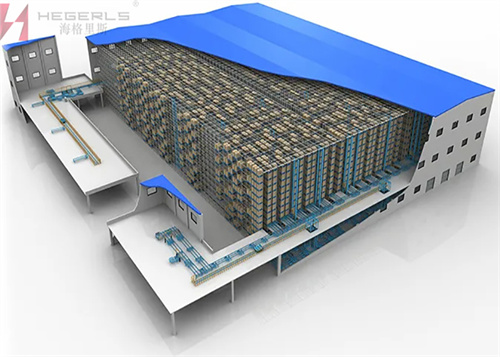

With the maturing of automated warehousing technology and the continuous improvement of the breadth and depth of industrial application, the scale of automated warehousing market will also be higher, and more and more automated three-dimensional warehouses will be put into use. The three-dimensional intelligent warehouse of WMS system adopts artificial intelligence technology. In this regard, we can see that a lot of labor costs can be avoided in the process of daily operation. Not only that, but also reduce the consumption of enterprises. It seems like nothing. However, with the increasing labor force, the use of WMS system three-dimensional intelligent warehouse will bring very high efficiency to enterprises. Now let’s take you into the Hergels storage factory of haggis and have a look at the three-dimensional intelligent warehouse of wms/rfid system that can be used by enterprises!

So what modules does the WMS system three-dimensional intelligent warehouse consist of? The intelligent three-dimensional library is mainly composed of three modules, namely: system function setting and basic data maintenance module, procurement management module and warehouse management module. Among them, the development of the warehouse management system needs to adhere to the self-defined management rules of the system. The module guided by this rule is the system function setting module, which is used to define the operation password of the administrator; The basic data maintenance module is used for users to customize the basic barcode serial number according to the product situation, and the corresponding codes and serial numbers of different models of products are also different, so that the product database can be formed for deletion and addition at any time; The purchase management module is mainly divided into purchase order module, purchase harvest module and other warehousing module. These three modules are a connecting link and are related to each other. Without affecting inventory, the purchase order module can be used to fill in purchase orders; Purchase after the order is approved, and then receive the goods upon arrival. The inventory is automatically increased until it is received; Warehouse management module, this module has many functions and plays a big role. It not only has the function of product in and out of the warehouse, but also has the function of inventory management, provocation and inventory of products. The warehouse management system can automatically generate the warehousing order number in the inbound and outbound links. In the inventory management module, the tedious manual management is saved. In the special products warehouse module, the functions of special products and normal products can be maintained through the establishment of virtual warehouse management. In fact, relatively speaking, the intelligent three-dimensional warehousing system is not only these system modules, but also includes warehousing management module, query index data module, report generation module and resume query module. The completeness of functional modules is an important consideration in evaluating a warehousing management system. Therefore, when purchasing a warehousing management system, everyone should connect the functionality of the system with the salesperson, To ensure that it will not have a lagging impact on the company’s warehousing business in subsequent use.

What is the structure of three-dimensional intelligent warehouse?

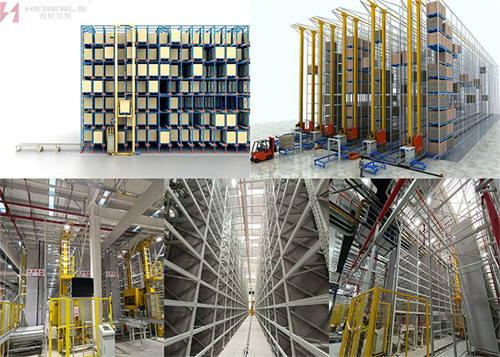

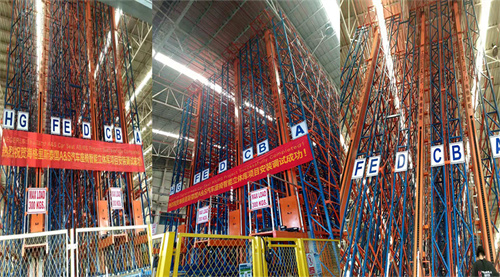

The automatic storage three-dimensional warehouse adopts three-dimensional shelves, stackers, conveying equipment in front of the warehouse, destacking equipment, information acquisition system (RFID identification device), box barcode scanning device, visual barcode batch identification device, RFID handheld terminal, server, touch all-in-one machine, computer operation terminal workstation, large screen display terminal, LED display screen, humidity control equipment, video monitoring system and other equipment, storage control system The automatic storage system composed of storage management system software and related auxiliary equipment can automatically stack and store the turnover boxes, and automatically record the storage location, which can greatly improve the work efficiency and save labor costs at the same time.

Hagerls – technical parameter reference of intelligent storage three-dimensional warehouse

Hagerls – functional features of intelligent stereo library

*Storage policy

1) Warehousing nearby: when warehousing, priority should be given to the location close to the warehousing conveyor.

2) Low level full loading: when warehousing, priority is given to filling the empty storage space at the lower level of the warehouse.

3) Partition storage: divide areas in the warehouse and store the specified measuring instruments in the same area.

*Stock in / stock out rules

1) Issue / receipt by asset batch, project and carrier scheme.

2) Emergency priority: you can set the priority of goods or tasks to be issued, and issue first in case of emergency.

3) First in, first out, priority is given to the date of verification or delivery.

4) If it is required to enter and exit the warehouse, it can be discharged through the specified measuring instruments or turnover boxes.

5) Mixed receipt enables mixed receipt of multiple batches of metering equipment.

6) Frozen warehouse function: lock the measuring instruments under the specified conditions without warehousing.

*Automatic counting

1) When performing the counting task, there is no need for manual intervention to realize the counting of the whole warehouse.

2) It supports the physical inventory in the region or the whole region, and can specify the equipment category, asset status, equipment type, wiring mode, project, chip type, roadway, shelf and other conditions for automatic inventory, and produce inventory reports.

Hagerls – operation principle of automatic three-dimensional storage equipment

First, the AGV robot drives along the specified guidance path to start the material box. Because it has the function of automatic obstacle avoidance, it can automatically complete the transfer of various goods in the warehouse, and the efficiency is three times that of manual work. Then the AGV robot will access the door through RFID. RFID, also known as radio frequency identification, is a communication technology, which can identify the RFID chip loaded on a specific target through radio signals, and read and write relevant data. In this way, the staff can read the material box information from a long distance, know the material type, downstream customers, storage location, etc. in each material box, and realize the “interconnection” of cargo information.

When the AGV robot arrives near the robot hand, the robot hand receives instructions, accurately positions, and unpacks, stacks, and picks the goods, with an accuracy of 100%, which will effectively replace the complex handling work harmful to health. When the material box is placed on the conveying line, it completes the conveying task.

Finally, the bins will be placed and taken out intelligently by the stacker and sent to the downstream production plant according to the instructions. The stacking function can effectively improve the space utilization rate of the warehouse, saving 30% of the space compared with the traditional flat warehouse.

Then, how should manufacturing enterprises build their own exclusive intelligent storage system?

There is only one principle, which is to carry out intelligent warehousing transformation according to the actual needs of enterprises. Specifically, it should be customized according to principled planning, site process scheme planning, intelligent equipment options, determination of technical parameters, project implementation quality control, etc. No matter how advanced intelligent software and hardware are used, the above principles must be followed in order to truly achieve the purpose of intelligent warehousing and enhance the competitiveness of enterprises.

Most enterprises have realized the importance of intelligent warehousing system, but when they really plan, they find that they have not developed and implemented the talent reserve of this system. If it is all developed by the enterprise itself to overcome the design, technology and material problems, it obviously does not conform to the principle of giving priority to economic benefits, time benefits and production efficiency. At this time, it is a wise choice to introduce a professional supplier of intelligent warehousing and logistics system.

Hergels is a national high-tech enterprise integrating R & D, production and sales. It is committed to becoming a pioneer in the professional service of intelligent warehousing and logistics. It is mainly engaged in the integration of storage shelves, warehousing and logistics equipment, robot systems, intelligent logistics equipment, automated three-dimensional warehouses, etc., and provides enterprises with intelligent logistics solutions, intelligent warehousing solutions, intelligent sorting solutions, intelligent equipment and software system research and development, And system planning, design, consulting and other integrated solutions to help it build a digital intelligent factory and promote the transformation and upgrading process of Intelligent Manufacturing in China.

Post time: Jul-29-2022